Materials:

The type of rigid materials available when using the CNC Machining process are virtually unlimited. We can source whatever materials your design requires. Some of the most common materials we utilize are:

Metals: Aluminum, Low-Carbon Steel, Stainless Steel, Brass, Copper, and more. Check out the prototyping properties of metal. Contact us about other possibilities.

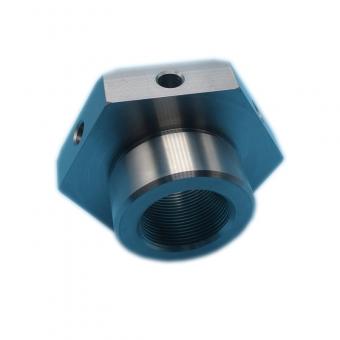

CNC milling parts, titanium casting parts

CNC processes : cnc machining, milling, turning, EDM laser cutting

Material : steel, stainless steel, titanium, aluminum

Painting : painting, texture, powder coating

Surface finish : nickel plating, zinc plating, anodizing, chrome plating

CNC machining parts and turned parts

Company Profile:

|

Company advantage

|

|

With the advanced and high-tech machines, we are capable of producing tight tolerance machined parts as per the drawings to meet your requirements. The picture shown is the customized product we make for our customer, for reference only. We will be pleased to be at your service.

|

Material:

Steel, stainless steel, aluminum, zinc, copper, brass, plastic etc

Machining process:

CNC machining, milling, turning, drilling, planning, welding, laser cutting

|

Company advantage:

1.Professional techniques and rich experience

2.ISO9001:2000 Certificated

3.Provide ODM/OEM service

4. Advanced equipment, excellent R&D teams

5. Strict quality control system

|

Surface treatment:

Polishing, chrome/zinc/nickel plating, power coating, anodize, E-coating

Applicable industry:

These parts are used in automotive, electrical, building, furniture, machine assembly, computer components, air-condition industry etc.

|

Applicable industry:

These parts are used in automotive, electrical, building, furniture, machine assembly, computer components, air-condition industry etc.

Features:

1. The accumulative error of grinding grade accuracy is 0.015mm/any 300mm;

2. There are straight tooth / helical tooth type, suitable for various use conditions; the helical tooth type is right-handed angle 19°31′42″

3. There are heat treatment type/quenching and tempering type, grinding grade/finishing milling grade, the same module, various strengths, various precisions;

4. It has a square/round appearance, which is easy to integrate and use; it can also be flexibly selected according to customer needs

This product can be used on racks required in textile industry, industrial machinery, hardware, machine tool, automobile industry, etc.

Focus on excellent rack manufacturer--marketing racks used in machine tools, industrial machinery, automotive industry, hardware industry worldwide Suitable for all kinds of CNC machine tools: cutting machines, lathes, milling machines, drilling machines, grinding machines, automatic mechanical systems (Robot arm), automated storage system, etc.

Taiwan's sophisticated grinding racks, a symbol of speed and precision, the world moves because of me. Adopt excellent grinding and gear making technology. Various tooth shapes, complete specifications of straight and helical teeth, module 0.5~14, racks can be connected once Processing length up to 3,000mm Heat treatment method: high frequency treatment and quenching and tempering treatment Surface treatment: grinding, non-grinding and blackening

Why Choose Us?

We provide service of the whole aluminium industry chain

We are fully committed to being the leading supplier of aluminium profile, precision tubing, aluminium sheet, plate, strip, foil, aluminium machining parts, stamping parts, and aluminium die casting parts. With more than 15 years' experience in customized precision machining services, we are committed to providing high-quality products at competitive prices.

Material Strength – What strength profile does your final CNC machined component need?

While “strength” may refer in part to the weight bearing load that a material can handle, there are ways that a material’s strength ability can be divided. Below are four strength properties to consider when selecting a material to machine:

Following these tips will help to ease the burden that comes with selecting the correct and most cost-effective material for your next CNC machined components. If material selection still feels intimidating, feel free to contact our specialists atto help guide you through the process.

Our advantages

Compared with domestic racks, Taiwan racks are significantly higher in accuracy and service life than the former, and rack accuracy is also significantly higher than the former, supplemented by strict quality supervision to produce high-quality transmission products.

(1) The accumulative error of grinding grade accuracy is 0.015mm/300mm (any 300mm);

(2) It has a straight tooth/helical tooth profile, which is suitable for various conditions of use;

(3) With heat treatment type/non-heat treatment type, the same modulus can have multiple strengths;

(4) It has a square/circular appearance and is easy to integrate and use;

(5) Various materials: alloy steel, stainless steel, engineering plastics (POM), etc.

Compared with many imported racks, Taiwan racks have great advantages in terms of cost performance. We set up offices in China to sell directly, which is more direct and efficient in product after-sales service! Because we believe that only with fast and efficient service can we achieve high customer satisfaction.

We are a manufacturer of high-precision grinding racks. The product manufacturing process adopts various high-quality equipment and dedicated technology. Under the operation of strict supervision and quality control, we can complete high-quality products. The company uses imported machines from Germany, which can be used in the original On the basis of ensuring that the delivery time and quality of the grinding grade racks fully meet or even exceed the requirements of customers.

F A Q

русский

русский español

español 中文

中文

Leave A Message

Leave A Message

IPv6 network supported

IPv6 network supported