-

Industry-specific attributes CNC Machining or Not Cnc Machining Material Capabilities Brass, Bronze, Copper Other attributes Place of Origin Fujian, China Type DRILLING, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping Micro Machining or Not Not Micro Machining Model Number none Brand Name none Material Copper/Brass Keyword tight tolerance Finish clear anodizing Tolerance 0.05mm OEM/ODM Accecpted Drawing Format 2D/(PDF/CAD)3D(IGES/STEP) MOQ 100pcs Logo Accept Custom Logo Equipment cnc turning and milling machine Product name Medical Device Accessories Packaging and delivery Packaging Details Pearl cotton individually packaged then packed with wooden boxRead More

-

Industry-specific attributes CNC Machining or Not Cnc Machining Material Capabilities Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys Other attributes Place of Origin Fujian, China Type Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping Micro Machining or Not Not Micro Machining Model Number none Brand Name none Material Brass Surface treatment Plated Keyword CNC Macining Parts Tolerance 0.01-0.05mm OEM/ODM Accecpted Drawing Format 2D/(PDF/CAD)3D(IGES/STEP) Logo Accept Custom Logo Packaging and delivery Packaging Details Pearl cotton individually packaged then packed with wooden boxRead More

-

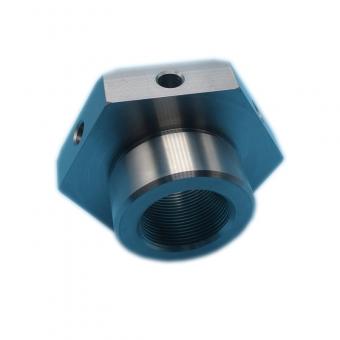

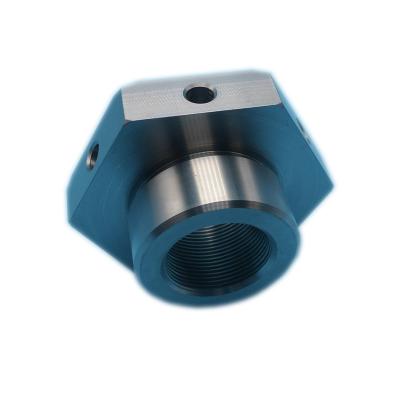

Industry-specific attributes CNC Machining or Not Cnc Machining Material Capabilities Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys Other attributes Place of Origin Fujian, China Type Broaching, DRILLING, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM Micro Machining or Not Not Micro Machining Model Number none Brand Name none Material Aluminum Alloy / Stainless Steel / Brass / Plastic Surface treatment Polishing, Brushing, Others Keyword CNC Macining Parts Finish Clear anodizing Tolerance 0.01-0.05mm OEM/ODM Accecpted Drawing Format 2D/(PDF/CAD)3D(IGES/STEP) MOQ 1 Pcs Logo Accept Custom LogoRead More

-

Designed and manufactured for sound performance and long service life. Our products are manufactured to exacting tolerances to assure interchangeability. Each component is made of quality material.Read More

-

This custom precision CNC turning chrome-plated stainless steel part comes from Prime, As far as CNC turning is concerned, stainless steel has good machinability which makes it easier for machining and treatment.Read More

-

cnc lathe machine can process large dimension all kinds of material spare partsRead More

русский

русский español

español 中文

中文

IPv6 network supported

IPv6 network supported