This article explains the advantages of using a CNC milling machine to make precise products;

Precision

One of the greatest focal points of utilizing CNC processing machines is that they can make parts precisely to determine. Since CNC milling machines depend on computer information to manufacture parts, they dispose of the plausibility of human blunder (error) common in physically operated machines. This implies that the machine can precisely make complex parts while accomplishing resilience as tight as 0.004mm.

With CNC milling, the human mistake is disposed of since the machines depend on computer information for creating parts. In any case, there are still a few controls over the fabricating handle by the administrator of the CNC machine. The precision of the CNC milling depends exceptionally and intensely on the administrator. It is down to the administrator to control the working environment and cutting apparatus calibration. They also have to recognize when the machine is getting gloomy and incapable to make the ideal results come about when in contact with the material. But in general, the chance of human error is essentially diminished.

Quick and Efficient

Conventional milling machines frequently require an administrator to physically alter cutting apparatuses depending on the cutting operation to be performed. Not as it were is this time-consuming, but it is additionally wasteful as conclusion comes about are based on the operator's judgment. CNC mills highlight turning carousels that can hold up to 30 diverse instruments. These instruments are naturally traded on the shaft amid machining operations, allowing cutting operations to be performed rapidly and proficiently. With CNC mills, the client will be able to have the parts prepared in a matter of hours, though ordinary strategies may take days (or weeks) to complete.

Wide Range of Material Options

CNC milling machines gloat compatibility with a wide extent of materials, counting plastics, metals, and composites. So long as the user has got pieces of the material, CNC mills will have no issue machining it.

CNC machines are congruous with a run of materials such as composites, metals, carving froth, unbending froth, phenolic materials, and plastics. Regarding material determination for CNC machining, features such as plan resilience, securing, hardness, stretch resistance, and warm resilience must be taken into consideration when choosing.

Affordability

We can converse the approximate accuracy, speed, and a ton of other focal points all day, but nothing beats reasonableness, particularly for businesses looking to depend on third-party producers. CNC milling is among the foremost reasonable modern-day fabricating forms. In reality, a CNC-processed component would cost less than a comparable 3D-printed portion.

Enhanced Staff Safety

CNC milling machines are kept separate from people and relieve the hazard that crops up something else. These machines can work without an administrator, in this manner restricting the plausibility of mishaps and decreasing the chance to harm human life and appendage.

Modern-day CNC milling machines are profoundly able to the degree that they can indeed alter their instruments naturally. Indeed, in case there's an alteration in the plan, it can be set in motion by changing the program without essentially coming in contact with the machine or person. As a result, human intercession is restricted to a supervisory part where they can remotely screen the execution of the program programs and preventive or receptive upkeep to maintain a strategic distance from breakdowns, which minimizes the one-on-one contact from the administrators and staff and makes the work environment more secure.

Higher Production and Scalability

After the administrator has modified the machine with the essential plan details, the production can take place or begin. Once the CNC milling machine has begun a production run, making the workpieces takes no time at all. As well as creating huge numbers of customizable parts, modern-day CNC milling machines are moreover exceptionally versatile. What makes them diverse from routine machines and manual generation forms is that a CNC milling machine can be modified to deliver one single part or several larger parts. There are no impediments to the number of parts the user can fabricate, permitting companies to utilize their assets and accounts more efficiently.

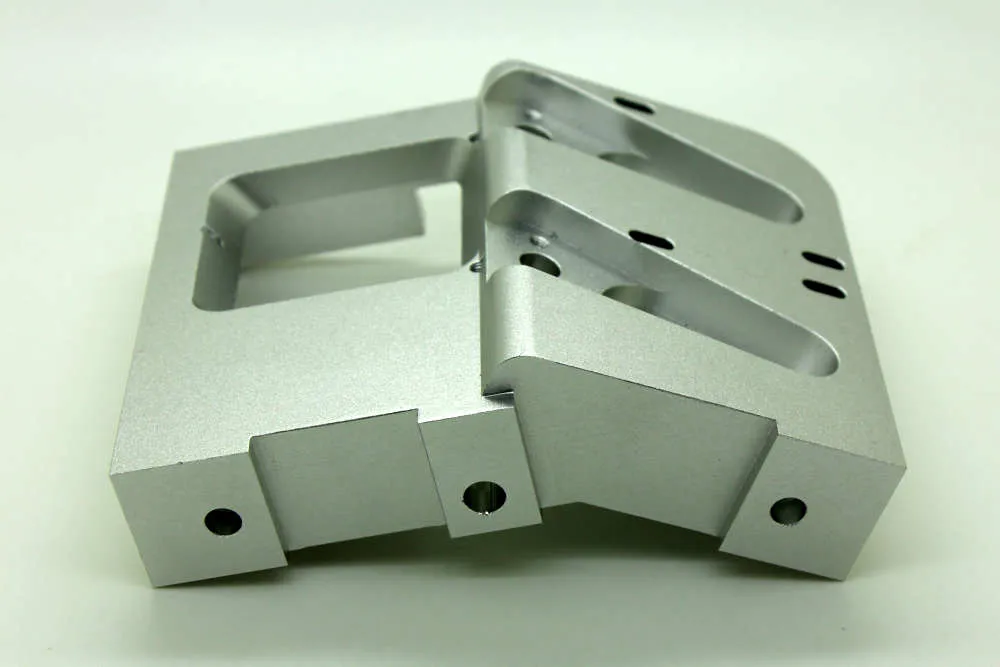

Improved Capabilities and can produce complex parts

A CNC milling machine ordinarily includes a turning carousel that can carry up to 30 apparatuses. These devices can be naturally swapped out amid the milling and machining process. CNC processing machines with advanced plan computer programs create complex shapes that a customary manual machine cannot duplicate.

CNC machines are much more proficient than any engineer, no matter how gifted or experienced. With the correct computer program, a CNC machine can deliver a workpiece of for all intents and purposes any measure, shape, or texture. A CNC milling machine has the ability to create the foremost complex parts.

The CNC milling machine can make essentially any component you might think of. These machines can perform a wide array of manufacturing and CNC processing operations, counting shearing, fire cutting, punching gaps, and welding metal sheets. Because of their extraordinary exactness, CNC machines can be utilized to deliver shapes of extraordinary complexity.

Less Maintenance

CNC ordinarily requires lower levels of support or constant maintenance. By large, the benefit includes changing the cutting executes at the demonstrated interim and a little sum of light cleaning. CNC milling machines need less administrative support, and any adjusting can be performed in-house without requiring proficient upkeep engineers, which spares money.