CNC Milling Machines are machines programmed, designed, and managed by Computer Numerical Control (CNC) systems to accurately and specifically get rid of materials by cutting a workpiece. They are computer aided. They require computerized controls and rotating different and numerous cutting tools to efficiently remove materials. The result of this machining process is to produce a custom-made product. And they are used on various products such as glass, wood, metal, and plastic.

The machining process in producing the custom workpieces is called milling. Milling involves taking a piece of pre-shaped material and placing it on the milling machine. Then using a rotating tool to chip the material in small quantities until the desired product is achieved.

The following diagram shows the various CNC milling machine parts that one machine has to perform its work efficiently. Several companies manufacture different milling machine parts such as Xiamen Prime Kunwu Technology Co., Ltd. This company specializes in making CNC milling machines with Steel parts as well as aluminum, bronze, titanium, stainless steel, and more.

There are numerous types of CNC milling machines with different parts, each with different uses. These machines are normally grouped under vertical and horizontal milling. When considering purchasing a CNC milling machine and its reliable parts, it is crucial to account for the qualities of the machines such as its shape and size, longevity, and stability as well as the dimensions of the CNC milling machine parts. The following are the types of these machines and their uses.

Vertical CNC milling machine

A vertical milling machine has a rotating tool that runs vertically. It has three axes where the table moves in different directions from side to side and front to back. These machines are cost-effective, simple to use, and very diverse in functionality. The vertical CNC milling machine is also further grouped in two.

· Bed mill – in this machine, the spindle moves on its axis and the table moves perpendicular to the spindle.

· Turret mill – in this machine, the table operates perpendicular to the spindle and the spindle is fixed position.

Vertical milling machines are used in various industries such as electronics, medical, automotive, and aerospace projects for producing high-quality parts. Since it is simple to set up and use, it is the best option in making prototypes. They are used in creating; box-type parts such as spindle boxes, complex curved parts such as engine impellers, and irregular parts such as brackets.

Horizontal Milling Machine

The functionality of a horizontal milling machine is similar to vertical machines— removing small parts of material from a workpiece. The tooling in a horizontal machine spin horizontally. And instead of three, it has a fourth rotation axis and sometimes even five. This machine is dynamic and complex, but it ensures that workers have a safe working area on one side of it and the table is on another side. This machine saves a lot of time in cutting because the worker can be there safely observing.

The horizontal CNC milling machine is suitable for creating large and heavy parts such as aircraft components. As well as irregular parts like helicoids and gears and, finally, parts that require milling on multiple sides at the same time.

A horizontal milling machining is ideal for applications that require pocketing, facing grooves, and slots. However, regardless of its complexity, this machine allows workers to perform their tasks as efficiently and save a lot of time while being safe. Horizontal milling machines are divided into Bed type, ram-type and planer type;

· Bed type – this machine has the worktable fixed directly on the machine. The bed-type machine can have one, two, or three spindles on the x and y-axis. Namely, known as the simplex, duplex, and triplex respectively.

· RAM type – this machine is not fixed to the worktable. It allows movement in the x and y-axis. But it is fixed to a moving housing ram.

· Planer type – the planer type is also having worktables fixed to the machine, but the spindle moves in different directions. This machine can support multiple, a range of different tools.

The horizontal and vertical CNC milling machines have further been divided into several other types that are available in the market right now. Some of these machines are as follows;

Double Column Machining Centers

This machine is used for larger-sized machines and parts. The double-column is designed to help with rigidity, and sometimes smaller-sized machines use this feature to help with more accuracy in the milling process.

The double-column machine is expensive because it is used in mold and die applications which require the highest level of production standards, accuracy, and efficiency.

Travelling Column Machining Centers

The movements are made by a traveling column with a spindle and a cutting tool. These machines are very slim and move in a y-axis direction, allowing workpieces with multiple clamping applications to work better.

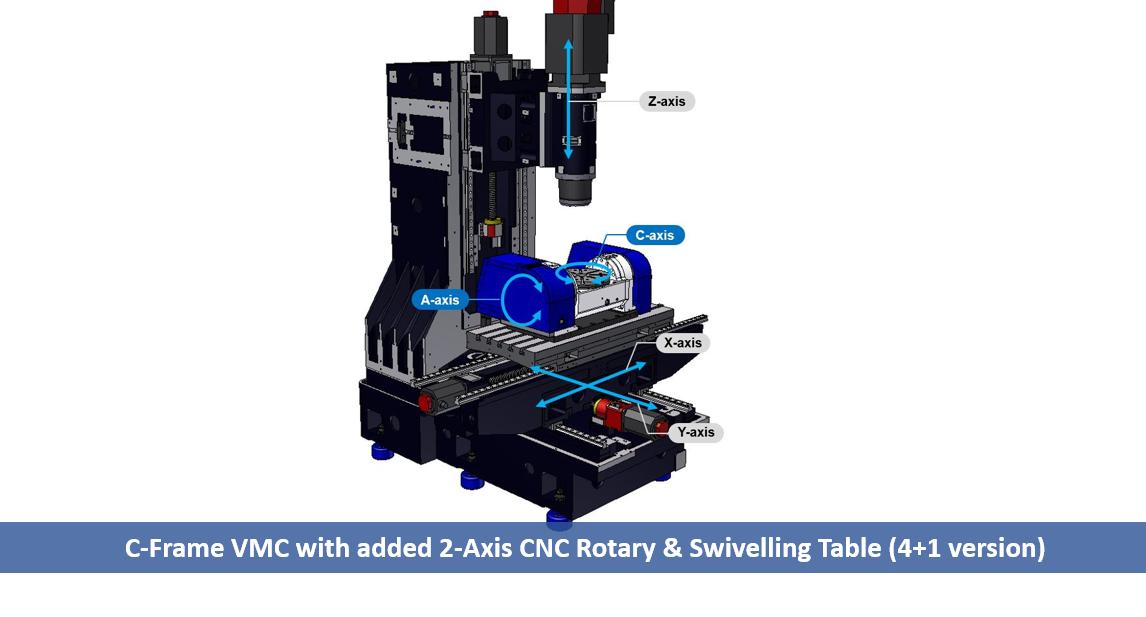

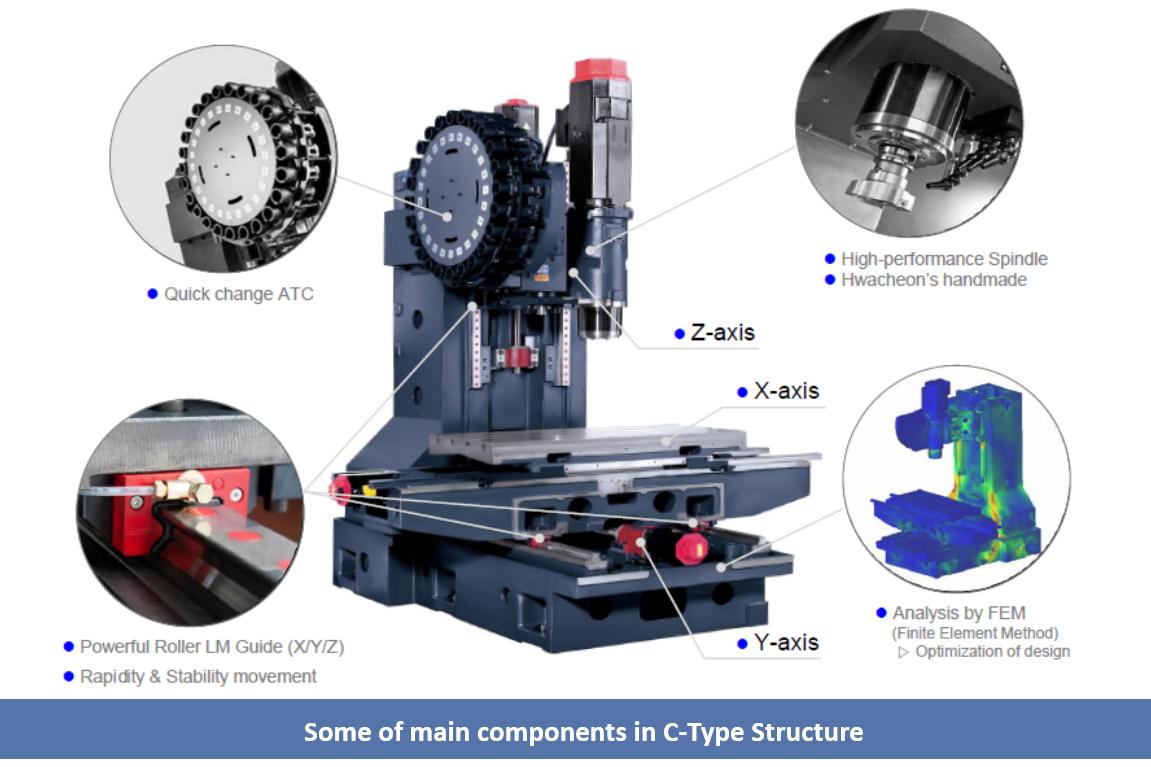

C-Frame Vertical Machining Centers

Vertical Machining Centers (VMCs) have a c- frame shape and are limited in size. They cannot be used in some machines because the space required for the machine is too big.

Several companies make CNC milling machines and their centers. One of those companies is Hwacheon Machine Tools in South Korea. And for reliable CNC milling machine parts, you can visit this Chinese company Xiamen Prime Kunwu Technology Co., Ltd. It is one of the best quality milling machine parts manufacturers, offering a variety of machine parts in various sizes.

CNC milling machines require less maintenance and can be used up to 24 hours a day. It is also a flexible machine. In terms of the software, it is up-to-date on all features and only a single operator is needed in working and supervising multiple machines at once as long as the right program is loaded.