CNC milling machines are machines used to create custom workpieces by cutting and shaving off other unused materials. They require computerized controls and rotating different and numerous cutting tools in order to efficiently remove materials. The result of this machining process is to produce a custom-made product. CNC milling machines are used on various products such as glass, wood, metal, and plastic.

The machining process in producing the custom workpieces is called milling. Basically, milling involves taking a piece of pre-shaped material and placing it on the milling machine. Then using a rotating tool to chip the material in small quantities until the desired product is achieved.

CNC machines are used in milling surface contours, profiles, die cutting operations and cavities. This is done by two or three axes milling machine on the table to be perfectly cut and milled. It is a complex machine and can be used in a wide range of industries such as military industry, automotive industry or aerospace industry.

There are different CNC milling machines with different axis such as a 2-axis CNC milling machine, a 3-axis CNC milling machine, a 4 and 5 axis CNC milling machine. all these machines are good to use depending on the material the user is working on the outcome the user wants to get from the material. They all offer different levels of flexibility and versatility and they are all completely automated. It is important for the user to pick the right choice depending on their project, cost and labor they are willing to put out on the project.

3-axis CNC milling machine

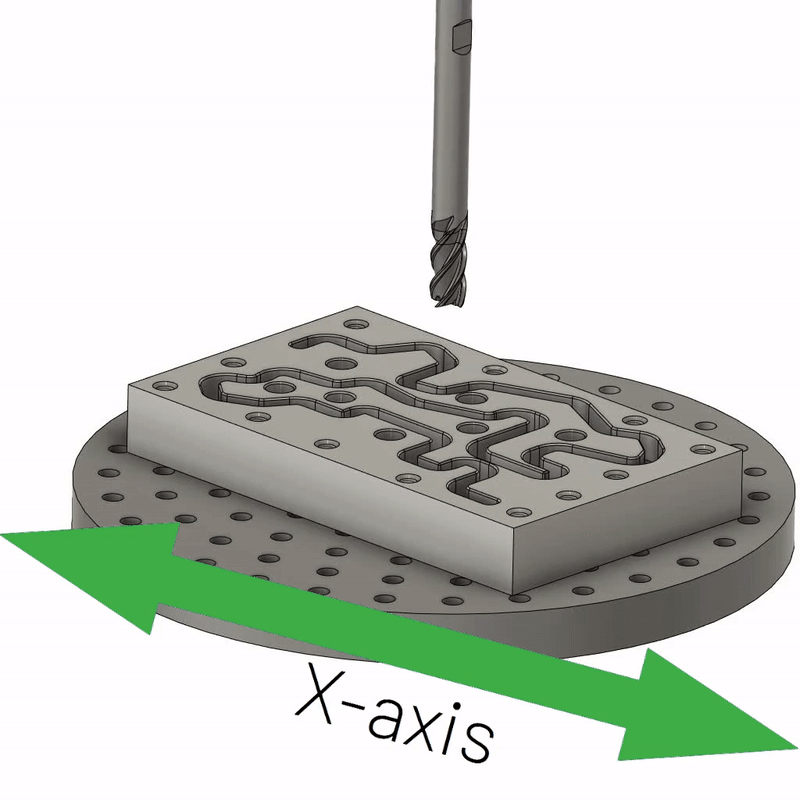

All the milling machines are automated. After the instructions are set into the computer the CNC machines start to work on the task. The 3-axis CNC machine cuts along three axes namely X, Y and Z. it also can go from left to right, up and down and front to back depending on the material used.

During the process of using a 3-axis CNC milling machine, the material is fixed on a machine bed. Then the rotating drills are connected to the spindle making it move along the X, Y, and Z axes, slowly cutting and shaving the material down to its final desired form. A 3-axis can only form non-conventional designs with deep and narrow cavities because it is limited to only three axes. For a more complex design the 3-axis machine operator will have to manually change the position of the workpiece. This will increase labor cost and the machine cost hence, slowing down the machining process and end up with a poorly finished workpiece.

5-axis CNC milling machine

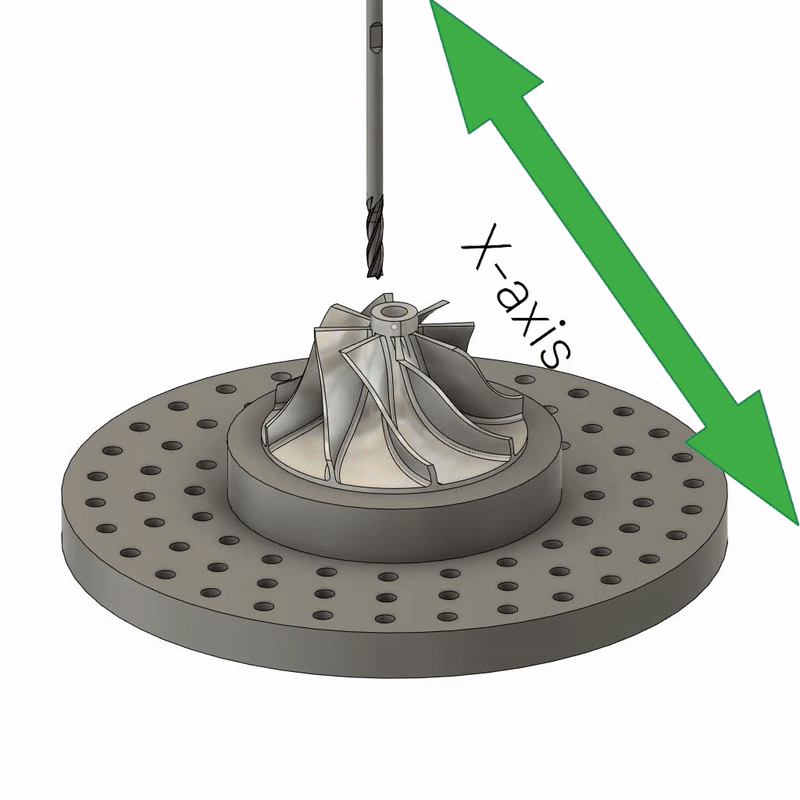

A 5-axis CNC machine can move in 5 different directions namely X, Y and Z as well as A and B. The operator places the material on the machine bed and the spindle rotates from all directions automatically without needing to manually change the position of the workpiece. A five-axis machine is very convenient and work well with complex creating designs whilst saving time and costs.

A 5-axis CNC machine is commonly used for medical, aerospace and, gas and oil industries. There are three kinds of 5-axis CNC machines namely the continuous, indexed and mill-turning 5-axis CNC machines.

An indexed 5-axis milling machine moves like a 3-axis milling machines in three directions hence, it does not automatically continuously maintain contact with the workpiece. But the machine bed automatically moves with the workpiece in the other two directions A and B. an indexed 5-axis CNC machine is most suitable for manufacturing jigs, housing and fixtures. The speed and complexity of an indexed 5-axxis machine is between the 3-axis and 5-axis CNC milling machine.

A continuous 5-axis CNC machine can rotate and move the work piece at the same time without needing to change positions of the workpiece. This saves a lot of time and cost for the operators. It is fast and offers a high quality and accurate finishing of the workpiece.

A Turning mill CNC machine has a CNC milling equipment with a workpiece attached to the spindle. The spindle rotates the workpiece in order to accurately make the finished product. All these machines are very expensive compared to 3-axis CNC machines because they require professional and experienced operators as well as other equipment to go with it.

The difference between a 3-axis machine and a 5-axis machine

The main difference is that a 3-axis CNC milling machine is only limited to three axes and a 5-axis CNC machine has five axes. They are both automated machines and versatile.

However, a 3-axis machine is more convenient for cutting flat surfaces and it is cheaper compared to a 5-axis machine. Hence, on a budget the best way to go is a 3-axis machine. the 3-axis machines are also simple to use do not require more expert professionals and can be run by one operator. Using a 3-axis machine also require less time for preparation.

On the other hand, a 5-axis CNC machine works on all sides without any physical contact with the workpiece from the operator. For a deeper and more complex project, a 5-axis machine is most suitable. It is very accurate and allows free movement of the workpiece.

Despite the differences, both the CNC milling machines require less maintenance and can be used up to 24 hours a day. It is also a flexible machine. In terms of the software, they are both is up-to-date on all features and only a single operator is needed in, and working as well as supervising multiple machines at once as long as the right program in loaded.

The Milling machines are both versatile and dynamic in their movements. They are easier to use in large projects and industries because they are automated and are flexible in positioning. They can be placed in a vertical or horizontal way to design materials better. The 3 and 5 axis milling machines are automated using a CAD program.