A CNC milling machine uses computer Aided Design (CAD) software to automatically cut the workpieces. Thus, it does not require manual cutting. Some machines need operators to run the software as well as move the workpiece in different positions for a more accurate finished product.

CNC milling machines are used in various industries to produce and generate several machines and equipment that are used in machines. Some of these industries are the aerospace industry, agricultural industry, automotive industry, medical industry, and so on.

Aerospace Industry

The aerospace industry uses complex and customized parts in making aircraft airplanes. CNC milling machines use computer numerical software to precisely create and craft these parts that can be used as a replacement for other parts on the airplanes, fuel bodies, prototypes for the aircraft as well as some structures on the aircraft.

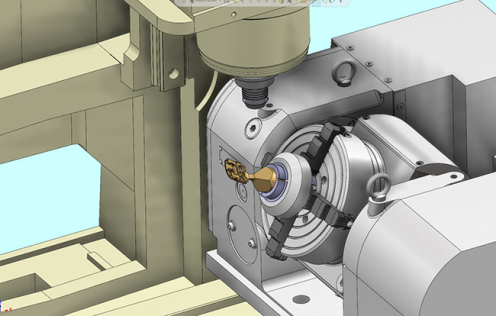

The machining services used in making aircraft must be certified and of high quality and accuracy. Hence, the 5-axis CNC machine is the most suitable option since it can move along five axes to create a specific complex design with a little ease. The machine is highly efficient and has the optimum speed to finish the work on time. The operators of this machine must be highly trained on how to run the 5-axis CNC machine to ensure high quality and accurate final product.

The aircraft also need smaller parts to be created using CNC milling machines such as electronic appliances needed to run the aircraft

Automotive industry

In the automotive industry, CNC milling machines have several applications such as manufacturing OEM parts. it is used in creating parts like piston rods, cylinders, flywheels, water pumps, and engine blocks. It can also be used in creating headlights for cars and motorcycles as well as engine spare parts.

Using a vertical and horizontal 5-axis CNC machine in the automotive industry is very suitable because it increases the production rate and reduces costs due to its efficiency.

CNC machines are also being used in enhancing and increasing the production of electronic and self-driving cars. Aided by Artificial intelligence (AI), the machines help create integral parts or components in self-driving cars.

Medical industry.

The medical industry is one of the largest industries where CNC machining services are widely applied. Mostly in creating safe electronic appliances (equipment) for treating patients. Some of this equipment are spacers, biopsy tubes, inserts, bone screws, hip stems, and so on. They are also used in creating prosthetic limbs to help patients improve their lives.

Most modern medical facilities are high-quality devices used by numerous specialists like optometrists and dentists. The medical industry uses a Swiss CNC machine for making bone screws. The machines are used in making large medical devices as well as smaller components that can be applied in fitting implants. The main parts that are produced in a machine shop are ventilator parts and medical screws.

Medical screws use titanium or stainless steel since they are inserted into the human body. They are in very high demand and are formed on lathes. The pieces need to be tightly placed together to avoid any loose screws that can harm the bones. These parts need to be made with high precision and accuracy to avoid any complications during surgery.

Energy industry

CNC milling machines are used in both renewable and non-renewable energy industries to manufacture high-quality components. Some of these components are fuel pumps, turbines, gearboxes, and valves. They are also used in creating nuclear technology parts, in hydroelectric power plants, and Air mills. The components created need to be precise and accurate to match the demand in the energy industry.

The CNC milling machine used in this industry is the 7-axis milling machine that runs horizontally and vertically. This machine is used in hydroelectric energy production to fabricate turbines and generate small and massive components. It is also applied in the solar and wind power systems to increase and improve the efficiency and performance of solar panels and wind turbine blade designs.

Military

The military uses milling services to create precise parts used in creating weapons and other items used in military base camps. Some of the items are firearms, UAVs, missile components, and drones. This requires a multi-axis CNC machine to create a large cruise missile. The process of creating these parts needs very little to no intervention or human contact, hence the use of computer-aided machines is very important. This reduces the risks of any accidents or injuries in the military.

The military also uses CNC machines in making aircraft, medical appliances, radar technology, naval ship components, and vehicles used in land and combat. Hence, the machines used are 5-axis CNC machines, and 7 as well as 20-axis CNC machines.

Electronic industry (consumer electronics)

Consumer electronics like smartphones, televisions, refrigerators, automotive parts, laptops, and other appliances and gadgets are created using CNC milling machines. Some of these electronics are small and hence, require micro-machining to create precise parts and quality finished products. most electronics use automatic computer-aided techniques to produce programmed machine parts.

Electronic devices need prototypes before the actual device is built and goes for production runs. CNC machines use computerized designs to create working prototypes to evaluate the efficiency and performance of the devices. A 3-axis and 5-axis computer-aided CNC milling machine is used in manufacturing small and large electronic devices. The machines need to be flexible to meet the demands of the electronic industry.

Agricultural industry

The agriculture industry uses CNC machines for creating parts used in crop harvesting. Some of this agricultural equipment are castings, gearboxes, incubator parts, gearboxes, and other electronic farming equipment. Some of these parts like gearbox casings, transmission housing, and cast parts are used for better plant growth by collecting products from the soil and retrieving the nutrients from it.

The machines usually go through three cycles in a year. This reduces the labor workload and saves costs of going through intense labor training and time consumption.

Every industry that uses CNC milling machines has different applications and is used in creating different products. Before choosing a CNC machine, the industries need to examine and test the machines to know whether they work for their particular needs.