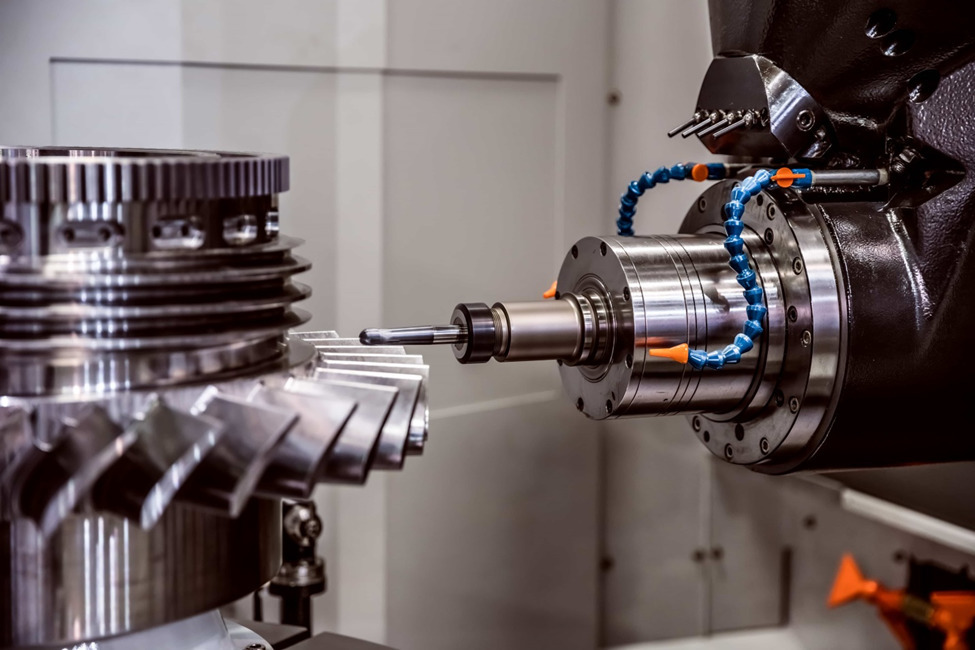

CNC milling machine is the method involved with machining utilizing turning instruments to slowly eliminate material from a workpiece. CNC processing machines are a pillar for industrial facilities all over the planet. These machine apparatuses utilize an assortment of cutting devices along at least one tomahawks to eliminate material from a workpiece through mechanical means.

CNC milling machines are regularly utilized in an assortment of assembling ventures: from businesses like aviation, transportation, cars, and oil boring/siphoning and refining, to clinical, FMC assembling, and accuracy designing areas.

CNC Milling Machines are machine worked cutting apparatuses that are customized and overseen by Computer Numerical Control (CNC) frameworks to precisely eliminate materials from a workpiece. The outcome of the machining system is a particular part or item that is made utilizing Computer-Aided Design (CAD) programming.

CNC machine steel is a combination of iron with roughly 1% carbon. Modest quantities of other alloying components like molybdenum and chromium might be added to work on their properties. Steel offers an extraordinary harmony among cost and usefulness since it is not difficult to machine and weld. It will, nonetheless, oxidize over the long haul and in this way needs surface medicines for assurance.

Steel is perhaps the most generally utilized assembling material and is utilized in each significant industry from development to car. Its expense adequacy combined with a few extremely helpful properties makes it an adaptable material.

CNC milling is a subtractive assembling process, 3-pivot and 5-hub cutting apparatuses are modified and overseen by PC mathematical control (CNC), eliminating material from the plastic or metal square.

Ø How does CNC Milling work?

They have different apparatus sets in light of productive cutters for a specific plastic or metal material. The machine then, at that point, quickly processes parts out of the square in a subtractive assembling process that utilizes 3-or 5-pivot processing. Machined plastic parts are left as processed, which regularly implies they show noticeable device marks. A few metal parts permit additional completing decisions. Whenever the run is finished and your necessary surface completion is applied, parts are boxed and transported presently.

Ø Why do we use CNC Milling?

CNC machining administration can convey machined parts, in both plastic and metal, quicker than it takes to get a statement from other, more conventional machine shops. Transfer a CAD document, pick the material and part amount, and let us know when you want the parts. We likewise offer several CNC explicit secondary administrations to help your task.

Ø Application of CNC Milling Machine

CNC Milling is an extremely flexible interaction that is utilized in many ventures. It is generally striking for creating accurate parts specifically for car and aviation enterprises. Parts, for example, motor parts, bushings, and exhaust parts. It is additionally vital assistance for clinical componentry, supporting with models specifically.

It is a significant innovation in the Oil and Gas industry for key parts in expulsion and for Industrial Equipment, for example, dances, apparatuses farm truck parts, and so on This is because of its capacity to make perplexing, exact, high-finish, high-resistance parts. Its stringing prospects are likewise key.

At last, its high accuracy, lightweight metals, and superior execution plastics settle on it a famous decision for the airplane business for some outside primary parts and inside parts for direction, divider boards, ventilation channels, and so on.

Ø How much does it cost to manufacture the CNC machined parts?

4 key factors add to your parts, raw material, machine time, labor, and speed. It will be nothing unexpected that a few materials are more costly than others, for metals, steel and aluminum are bountiful and have the most reduced natural substance cost per kg while for plastics Acetal, Nylon, Acrylic, and ABS will more often than not work out less expensive. In the range for metals you have more expert aluminum and tempered steels (containing costly alloying components) and for plastic glass-filled grades.

At a very good quality, you have materials like titanium (which is bountiful yet hard to refine) for metal and plastics like PC, PEEK, PSU, PPSU, PEI, and POM-ESD, by and large expected to meet a particular need. Things, for example, part intricacy and material machinability play an element here, and obviously, the faster you need something the more you are probably going to pay, make sure to analyze costs like for like, thinking about both cost and conveyance.

Ø Benefits of CNC Milling machine

· Product quality

The interaction is more exact than manual machining and can be rehashed in the very same way again and again.

· Increased efficiency

Computers are utilized to control the machines, the interaction is robotized thusly speeding up and nature of assembling. Considering machines don't tire or need breaks it makes it more proficient than manual machining.

· Safety

Utilizing CNC machines are a lot more secure than physically worked machines as they work behind a watchman or even a shut, straightforward wellbeing entryway.

· Cost-effective

Customary machining requires one administrator for every machine. This kind of machining requires fewer machine administrators since one gifted administrator can run a few machines all at once. Since the CNC is so precise it diminishes blunders from the assembling system and kills unnecessary waste.

Conclusively, CNC machining offers a solid answer for quickly producing the parts. The current methodology, utilizing an indexable device, figured out how to wipe out various set-ups of the workpiece. The deceivability program is a viable technique to distinguish directions for completing activities. Be that as it may, performing roughing activities inside a completing directions sets will in general oblige the roughing undertaking and causes a few shortcomings.